ELIMINATE THE RISK OF MISPLACED REINFORCEMENT

ENSURE COMPLIANCE TO THE DESIGN & BUILDING PRACTITIONERS ACT 2020

USE BLOCKAID LOCATING DEVICES AND SIGN THE DESIGNER AND BUILDERS DECLARATION WITHOUT RISK & COMPLY TO AS3700-2018 & NCC-2022

The NSW Building Comissioner is aware of masonry reinforcement location issues. The use of Blockaid Locating Devices will improve construction to overcome poor workmanship.

THE PERFORMANCE REQUIREMENT FOR REINFORCED MASONRY IN NCC-2022 IS IMPRACTICAL, IS NOT ADHERED TO AND FAILS TO PROVIDE A LOCATION MEANS TO ENSURE COMPLIANT CONSTRUCTION OF REINFORCED MASONRY. BLOCKAID LOCATING DEVICES ARE A “DEEMED TO SATISFY” SOLUTION TO MEET THE PERFORMANCE REQUIRMENTS FOR REINFORCED MASONRY

THESE PHOTOS OF A THREE STOREY MASONRY CONSTRUCTION IN NEWCASTLE ARE VERY CONCERNING. THE VERTICAL REINFORCEMENT HAS BEEN PUSHED UP AGAINST THE SHELL FACE OF THE BLOCKS WHEN IT SHOULD BE CENTRAL IN THE CORE. THE OWNER WILL BE FACED WITH EXPENSIVE RECTIFICATION FROM THE SIGNIFICANTLY REDUCED STRUCTURAL STRENGTH AND THE LACK OF GROUT COVER WILL GREATLY REDUCE THE DURABILITY.

Testimonials

The research revealed that the use of BlockAid resulted in a complete wall structure that met the requirements of AS3700-2001 Masonry Structures in terms of achieving correct reinforcement positioning, consistently achieving greater accuracy than conventional best practice. Moreover, it achieved a construction speed comparable with commonly encountered, low quality practices, and resulted in construction times 20% faster than best practice, wire tied techniques.

From our experience, BlockAid locating devices are the only chair that can guarantee that the wall will meet its design potential.

Paul Fitzgerald from Hamstead Homes raves about BlockAid locating devices – he loves them!

BlockAid ensured the wall was built to the specification and that a steel fixer was no longer required. BlockAid eliminated vertical lapped joints to save 35% of vertical steel and BlockAid eliminated lifting blocks over vertical steel bars.

To build a block wall without BlockAid now would be ridiculous, in fact, it would border on structural negligence.

I am convinced that this is the best procedure available to guarantee the perfect location of all reinforcement.

SAVE TIME, SAVE MONEY

With the horizontal reinforcement captured securely by BlockAid, the vertical reinforcement can be inserted in one length through the BlockAids, locating the vertical bars securely during the core filling process and eliminating the need to tie or weld the steel. There are significant savings in construction time by eliminating welding or tying. The time saved by using BlockAid to locate the reinforcement offsets the purchase price of BlockAid, providing risk free compliance at no added cost.

SAVE MATERIAL, SAVE MONEY

When BlockAid locating devices are used, the vertical reinforcement is inserted in one length through the BlockAids with no tying or welding required, even on Hi-Risk sites, such as petroleum, ammunition and gas storage, where welding is common practice. By inserting full length vertical bars, a substantial saving in material and labour is achieved, compared to welding multiple lapped vertical bars as the courses are laid.

SAVE LABOUR, SAVE MONEY

On Hi-Risk or Critical sites, such as petroleum, ammunition and gas storage, welding the vertical steel in place as the wall is being built, is common practice. With the use of BlockAid locating devices to accurately and securely locate the reinforcement, there is no longer a need to engage a steel fixer to weld the reinforcement, providing a substantial saving in labour.

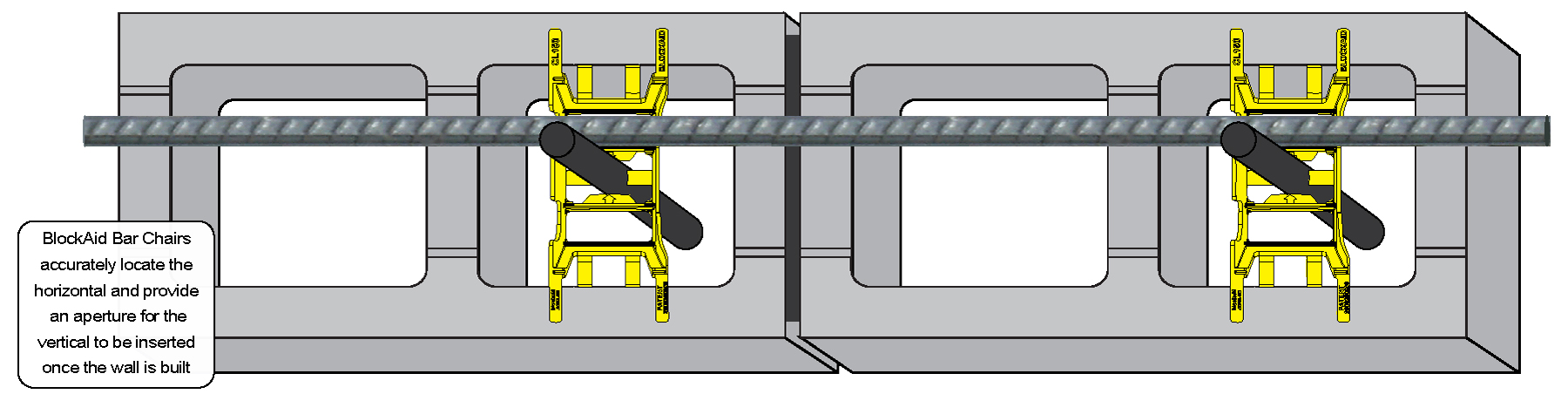

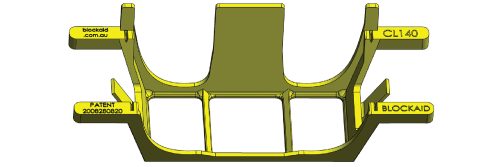

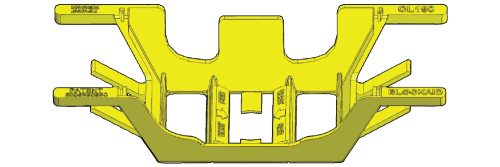

BlockAid locating devices accurately locate the horizontal reinforcement as the blocks are laid and provide an aperture for the vertical reinforcement to be inserted into the wall, resulting in an accurate lattice of reinforcement throughout the entire wall, to achieve compliance to AS3700.

Australian Governments, Engineers and Certifiers have a vested interest to specify the mandatory use of “bar chairs for blockwork” or “locating devices” to improve work practice and achieve compliance for block walls, thereby ensuring block wall assets are insurable.

* The Marine Environment (ISO Category 3) extends inland along the Queensland and NSW coast beyond the general distance of 10 kilometres from the surf coast to about 50 kilometres in exceptional circumstances, which includes the Gold Coast, Newcastle, Sydney and Wollongong, thereby increasing the minimum cover to 15mm in these extended areas.